Numerical simulation is an indispensable tool for understanding the physics of deforming structures and improving industrial processes in terms of efficiency, cost-effectiveness, quality, and environmental sustainability. FCC’s LaStFEM software is a versatile solution that is employed both independently and in conjunction with IPS IBOFlow® or Demify® to perform multiphysics simulations including structural-, fluid- and particle interactions. The software includes a wide variety of material models and allows analysis of beams, shells and volumes subject to large deformations and mechanical contacts.

Details

Finite element modeling opens the door to a diverse array of applications, prompting FCC to develop its in-house finite element software, LaStFEM, tailored for structural statics and dynamics. LaStFEM encompasses a wide spectrum of material models, catering to both metals and polymers, and enables comprehensive analyses of structures comprising beams, shells, and volumes, even under the influence of significant deformations and mechanical interactions.

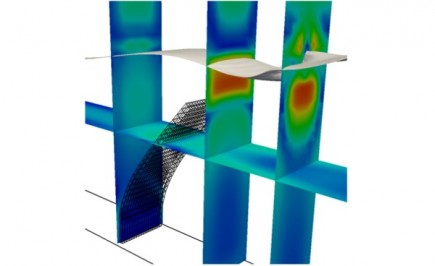

The core focus of the software lies in delivering optimal performance, making it a valuable tool for applications such as stochastic variation simulation in manufacturing assemblies, structural analysis of slender objects, and multiphysics simulations incorporating phenomena like thermo-mechanics, microstructures, fluid dynamics, fibers, and particle mechanics.

LaStFEM is implemented in C++ and engineered for seamless integration with IPS IBOFlow® and Demify® to target highly complex interaction problems. Additionally, LaStFEM features a Python interface, enhancing its adaptability for optimization and Artificial Intelligence (AI) applications. Our commitment extends to providing customized software solutions designed for precise products and processes, delivering exceptional performance to meet the stringent requirements for speed and accuracy demanded by our industrial clients.

For fiber-based materials, where the micro scale composition has a profound impact on the macro-scale properties, a dedicated structural network solver has been developed. The fibers are represented as chains of edges connected at nodes which in turn are bonded together with additional edges. The mechanical properties of the edge chains are modelled using beam equations. The network approach also enables fracture propagation analysis of the materials.

Application areas

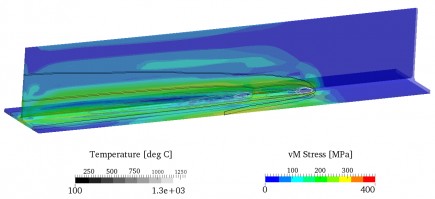

Structural mechanics at FCC finds application in diverse domains, including additive manufacturing, arch welding, spot welding, hemming and micro-structure simulation of paper (ISOP). In several projects we have a close collaboration with the department of Industrial and Material Science at Chalmers and the Fraunhofer Institute for Industrial Mathematics.

The network solver has been used to simulate paper properties, such as tensile stiffness and strength, bending resistance and Z strength, which normally is analyzed with fundamental test equipment by paper industry product development teams.