Particle simulation, driven by the discrete element method (DEM), is transforming how the industry deals with the virtual development and problem-solving of particle-machine systems. From optimizing bulk material handling to enhancing heavy machinery and additive manufacturing, DEM provides the accuracy and insights needed to solve complex industrial problems. At FCC, we research and develop particle simulation methods using our DEM software platform Demify®, which helps companies transform their development towards incremental technology improvement and innovation breakthroughs.

DETAILS

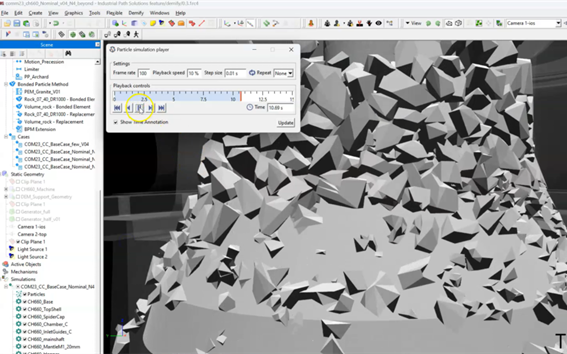

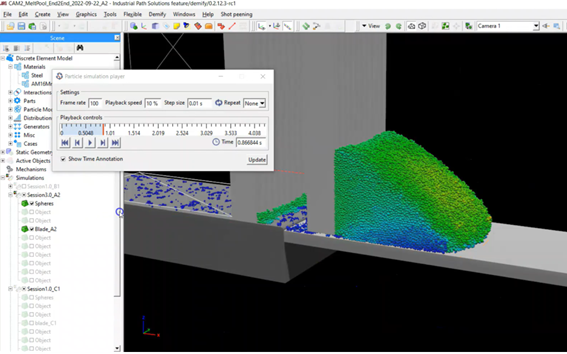

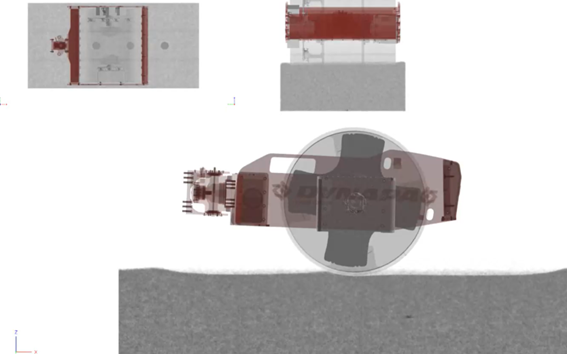

The Demify® solver is built using a modern C++ Nvidia CUDA framework for efficient GPU and CPU parallelization. The modelling of different types of granular materials requires different particle shape representations. The solver incorporates four main shape descriptions: single spheres, clustered multi-spheres, non-convex polyhedrons, and convex dilated polyhedrons. The dilated polyhedrons are also possible to compound using convex decomposition to form non-convex shapes. The computational performance of DEM is highly dependent on efficient collision detection. The collision detection scheme in Demify is based on a unique boundary volume hierarchy (BVH) algorithm implemented on the GPU. The BVH algorithm has the added benefit, compared to grid-based collision detection, of allowing large spatial domains.

In order to enable fast engineering value generation using simulation, it is critical that the interfaces are flexible and easy to use. Demify can be used both in the API mode where the solver is simply used as a Python library. This gives researchers and engineers complete access to all the underlying features as well as the option of integrating their own computations and couplings. The Graphical User Interface implemented on the IPS platform allows for both configuration of DEM cases with large and complex geometries and motions as well as for post-processing and visualization of results, all in the same view. Multiple results can be loaded, which is a great feature for e.g. problem-solving and concept development where the user needs to compare different simulations.

In some applications, multi-physics coupling to the finite-element method (FEM), multi-body dynamics (MBD), and computational fluid dynamics (CFD) is necessary. Demify allows for efficient coupling either to our in-house solvers or to external software via e.g. Functional-Mockup Interface for MBD. Demify also includes a smooth-particle hydrodynamics (SPH) GPU solver that enables efficient simulation of particle-fluid interactions.

APPLICATION AREAS

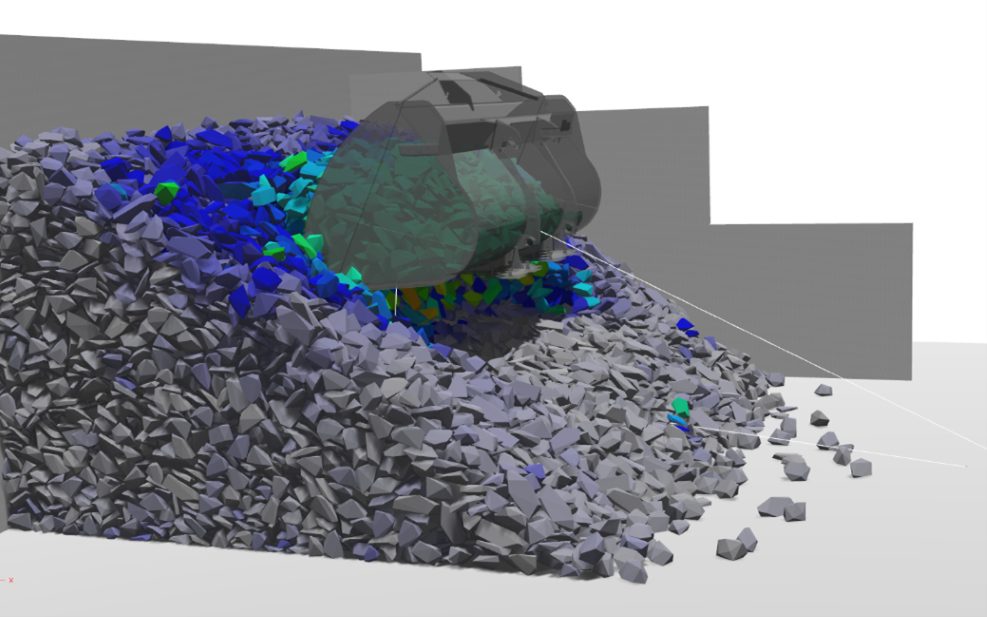

Our group conducts public and industrial research projects relating both elevating numerical performance and capability or investigating a particular scientific question. Such questions can be e.g. related to particle segregation, particle fracture, or other physics-related issues. We also offer organizations the development of customized virtual development environments. Such projects typically advance the level of the numerical representation of the system to a sufficient level of prediction faster. This enables engineers to reach a value-adding state in a more cost-effective manner.

Particle simulation methods can be used in a wide range of industrial fields, such as:

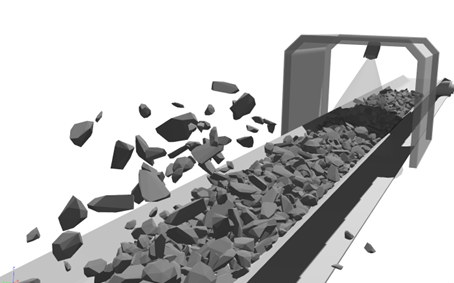

- Minerals processing

- Aggregate production

- Heavy Machinery

- Roads and railway construction and operation

- Pharmaceutical

- Additive manufacturing

- Agriculture

- Shot peening and blasting

- Bulk materials handling

___________________

If your organization is interested in DEM simulations to support your development, FCC can provide research services to develop a customized virtual environment tailored to your needs.