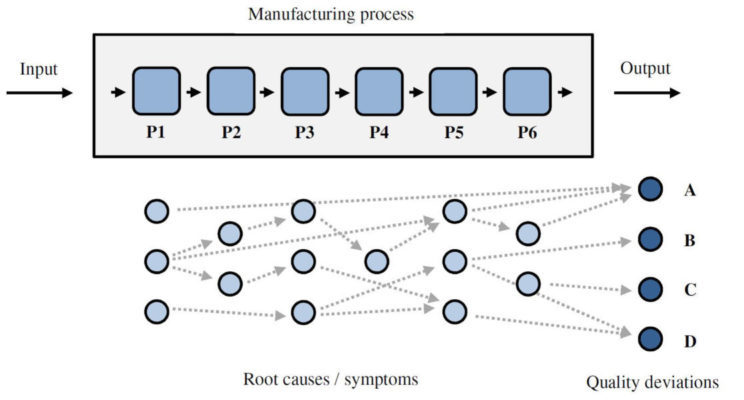

The vision of the project Root Cause Analysis of Quality Deviations in Manufacturing Using Machine Learning (RCA-ML) is to develop machine learning and big data analytics methods for identifying root causes of failures and quality deviations in manufacturing processes. The recent developments in machine learning and big data analytics present opportunities to utilize the large amount of data that is gathered at manufacturing sites for analyzing the manufacturing processes from a quantitative and data-driven perspective.

Today the root causes of failures and quality deviations in manufacturing are usually identified using expert knowledge existing at each separate manufacturing site. The experience of the staff at the sites constitutes the basis for describing the causal correlations between different process steps and the output failures/quality deviations, and manual methods are then employed to identify the root causes for the failures.

The purpose of this project is to study and analyze machine learning methods for automating the process of identifying and back-tracking root causes in manufacturing; a purpose which is in alignment with the digitalization and automation visions of the two industry parties of the proposal, SKF and FlexLink. By developing automated processes where the expert knowledge within the companies is digitalized through sensor solutions and used in machine learning methods, the companies ensure that the knowledge can be transferred easily between different manufacturing sites as well as secured for future use. The developed methods within the project will be generic, module based, and easily extendable for applications in other industries where root cause analysis is crucial for maintaining high quality and throughput.

The partners in RCA-ML are SKF, FlexLink, Fraunhofer-Chalmers Centre, and the computer science and engineering department at Chalmers University of Technology.

Figure 1: A schematic illustration of a manufacturing line consisting of six process steps (P1-P6). Four quality deviations/failures (A-D) are illustrated with possible root causes and symptoms that have causal correlations with the quality deviations.

The method development within the project relies on the competence at Fraunhofer-Chalmers Centre (FCC) and Chalmers University of Technology within machine learning, big data analytics, and software development. An integral part of this project will be the development of a software demonstrator. The integration of developed methods into a common platform will facilitate validation of both function and performance. Furthermore, a task driven and user friendly graphical user interface of the software demonstrator will alleviate communication and feedback between the project participants but also in communicating and demonstrating the project results to a wider audience.