Volvo Cars is now implementing a new process and software support based on RD&T and IPS for Inspection Preparation and Automatic Off-line Programming of CMMs. The return of investment will be faster inspection preparation, programming and improved measurement equipment utilization. The implementation is based on validated research results from FCC, Wingquist Laboratory at Chalmers, SWEREA IVF, Volvo Cars, and Saab Automobile within the VINNOVAs MERA program.

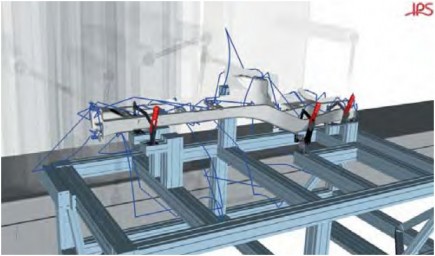

The inspection preparation contains three steps; (i) the inspection task is defined by breaking down product and process requirements to geometrical inspection features, e.g., a hole or a slot, on part and subassembly level, (ii) the inspection rules define how a feature should be measured, i.e., number of points, local measuring coordinate systems, and allowed probe configurations, (iii) the final step is to program the motions and sequence of the Coordinate Measurement Machines (CMMs) that perform the actual measurement. The automatic CMM programming contains three main math based algorithms for motion planning and combinatorial optimization. The first step is a feature accessibility analysis to find a set of probe configurations of minimum size that can reach all inspection points with collision free CMM configurations. This can be done by solving a binary LP problem. The next technology used is Path Planning where the collision free CMM motions are generated by automatically finding via points and probe reorientations between the inspection features.

Complete path planning algorithms, which always find a solution or determine that none exist, are of little industrial relevance since they are too slow. In fact, the complexity of the problem has proven to be PSPACE-hard for polyhedral object with polyhedral obstacles. Therefore, sampling based techniques trading completeness for speed and simplicity is the choice. Inspired by the two most popular probabilistic methods FCC has since 2003 developed a novel deterministic path planning algorithm implemented in the IPS software. The last step is sequencing where it is decided in which order and with what probe configuration the CMM should inspect to minimize cycle time. This is a generalization of the classical Traveling Salesman Problems (TSP) which has been solved by a new direct method for grouped problems with node alternatives.