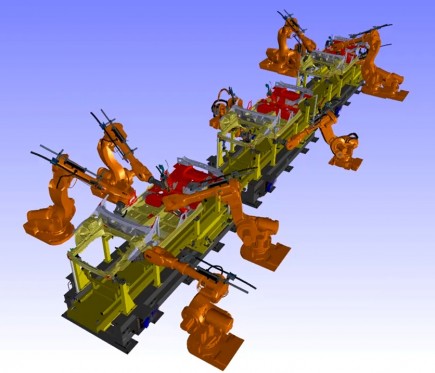

In today’s automotive industry, although most development is done virtually, some decisions still lack a solid mathematical basis. IPS Robot Optimization is an intuitive software application which, when presented with geometry and tcp positions of for instance stud welds, guarantees optimal and collision free robot paths for single- or multi-robot stations.

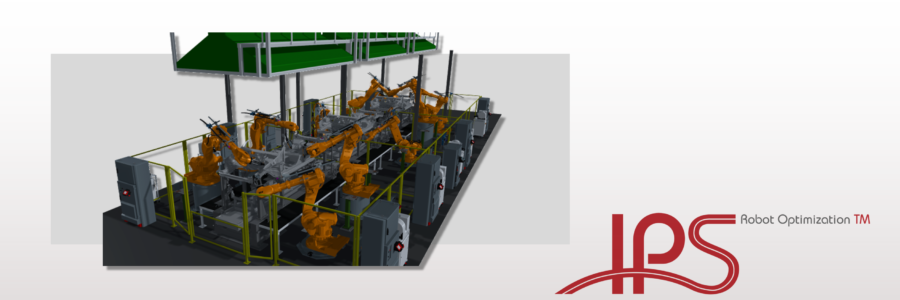

Application of the automatic line balancing method shows

- 25% better equipment utilization, and

- 75% reduction of offline programming- and commissioning costs.

The method also enables

- Concurrent manufacturing engineering and product development,

- Increased insensitivity to late changes,

- Backup solutions for robot breakdowns